DESIGN AND CONSTRUCTION

LABORATORIES, PRODUCTION AREAS WITH HIGH AIR CLEANLINESS REQUIREMENTS

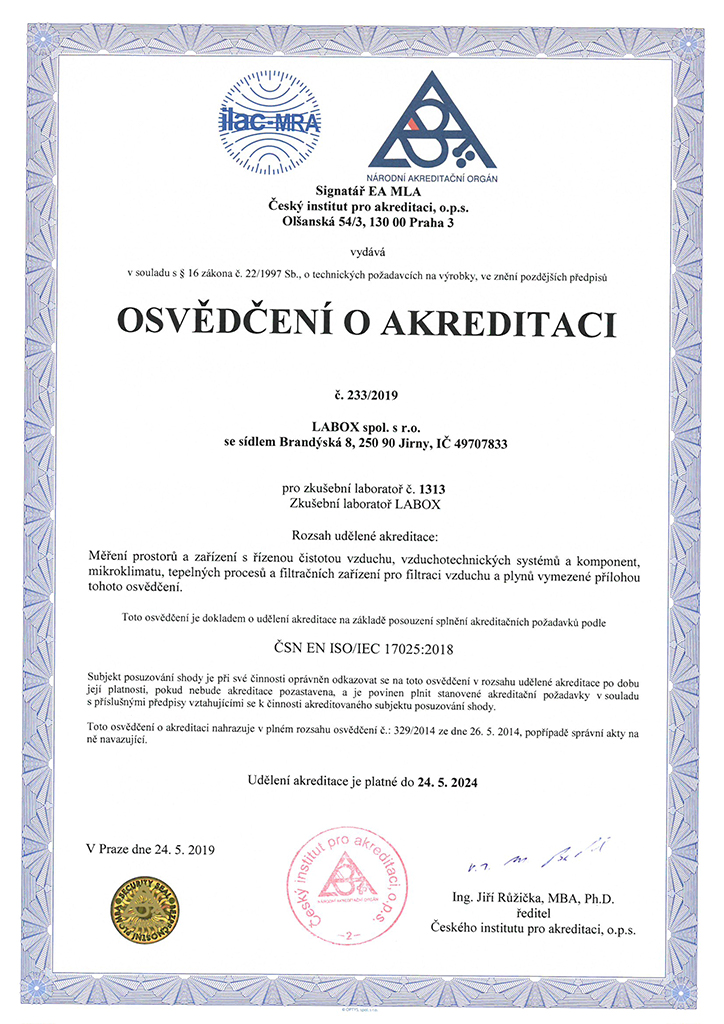

we provide turn key delivery, i.e. full provision of all activities realted to respective investment, i.e. from order specification throught working out a study and implementation design, obtaining relevant permits, the implementation itself, commissioning of the device in pilot runn after qualification possibly also qualification (DQ, IQ, OQ, PQ) of the clean room and technology installed. Additionally we provide the supply and installation of continuous monitoring. All activities are executed according to the LABOX project managment system, mostly streamlined in years of experience, which is used for investment actions of this type. All activities are also covered by quality management according to ISO 9001:2016, which is independently revised every year. In the case of turn-key deliveries, the investment project is completed by qualification, carried out by and accredited testing laboratory according to ISO/IES 17025 standards. Follow-up service is provided by our professional service department also in 24/7 mode.

- processing tissues and cells

- preparation of cytostatic drugs

- production and processing of radiopharmaceuticals

- PET Centers

- IVF Centers

- nanofiber production (nanotechnology)

- operating theatres

- microbiological laboratories

- biosafety laboratories BSL3 BSL4

- virological laboratories

- operational, research, manufacturing and inspection premises

- automotive, electronic and optic production

- premises with high-standard requirement on cleanliness (dustlessness), temperature or humidity

COMPETITIVE ADVANTAGES

- professional and experienced team

- maximum speed and flexibility

- cost-effective

- turn-key solution

- controlled project coordination and implementation

- full certification with worldwide validity

- providing full post-warranty maintenance services (including service 24/7)

and continuous monitoring

LABOX SUPPLIER SYSTEM

|

CONSULTATION WITH CLIENT - STUDY The clean room technology is very demanding in terms of money, deserves detail analysis and mainly determination of an ideal construction method, to make it as economically efficient as possible. Always required service life has to be considered, besides the technological requirements. In addition to the technological requirements, the desired service life must always be considered. Our professional team has more tha 30-year experience in supplies of clean rooms, and regards every clean space individually, taking into account maximum efficiency of the investment for the client. Targeted condultation and familiarisation with requirements are therefore the foundation stone of final success. The result of this step should be elaboration of a study which will represent the base for the following project documentation creating phase. |

|

DESIGN PHASE Once the main conception is known, work on the primaty design documentation begins to be submitted to supervisory authorities. Mostly it is a project for building permit which has to be presented to the building office. If there are more participants in the proceedings, such as State institute for Drug Control (local FDA) or National Institute of Public Health (NIPH), we provide the possibility of preliminary approval of the draft design. In case of turn-key delivery, project works on the implementation documentation are worked out so that the construction itself can begin already in the course of the project phase. This is achieved by a sophisticated system that allows coordination on that level by means of which we can reduce significantly the total time of invesment implementation. |

|

CONTRUCTION In case of an turn-key delivery this part of investment begins already in the course of the project phase. All steps are precisely defined, in order to ensure both quality and timetable. |

|

MEASURING AND QUALIFICATION No delivery is completed unless necessary measurings are accomplished, along with verification of the functionality of all systems and devices. We provide all measurings, qualifications and validations by means of a chain of accredited testing laboratories (ISO/IEC 17025), i.e. through maximum authorisation and independence on the results. All results are valid not only within the Czech republic but internationally. We provide a chain of tests as follows:

|

|

WARRANTY AND POST-WARRANTY SERVICE Upon handover of completed work to user for usage, the works on the project do not finish for us. This is the time when we most functionality and operativeness of the entire work is necessary, often more this time than prior to its completion, in order to avoid any uncontrolled failures and extraordinary events and expenses. This is taken care of by team of high experienced technicians who provide regular maintenance and service of supplied devices, and also provide the client with full information about potential operation costs (such as replecament of filter inserts, etc.), expected life of the technology and recommendations for renewal. A measurement group is also activated to ensure regular revalidation and a monitoring. Based on the client´s needs and technology we also provide 24/7 service availability, comprehensive facility management for all technological and laboratory equipment. As a premium service, we operate the state-of-the-art dispatching system for real-time technology monitoring LBXCON. Thanks to this system, we have an immediate overview of the status of the technology, the possibility of remote control and data analysis, audittrail, and timely and targeted response to any critical situations, which significantly reduces operating costs. |

24/7 service and support

fast response time

surveillance center and hotline

ARE YOU PREPARING, PLANNING OR THINKING ABOUT BUILDING A CLEAN ROOM?

Contact us! We are able to implement your project at all stages, from initial consultations to construction, validation and excelent services. Contact informtion is here. You can send us a general inquiry using the general form. Alternatively, you can use a specific:

- Czech chamber of Authorized Engineers ČKAIT

- Asociation of Mechanical Engineers ASI

- Asociation of Accredited Laboratories ILEC

- Design and delivery of EMS environmental continuous monitoring (particles, temperature, humidity, pressure, CO2, O2 etc.)

- certification, qualification, validation and service of cleanrooms and technologies

- consultation in the area of cleanroom technology

- manufacturing and installation of special rooms accessories (open door signalization, clean room phones, differential pressure gauges, etc.)

- laboratory equipment (furniture and lab tech equipment)

Contact us! We are able to implement your project at all stages, from initial consultations to construction, validation and excelent service. Contact information is here.

You can send us a general inquiry using the general form.

Alternatively, you can use a specific:

for Your

professional work

Cleanrooms are spaces with controlled air purity. They are used where there are defined requirements for cleanliness, temperature, humidity and microbial cleanliness. Clean rooms are defined by EN ISO 14644, GMP, VDA, etc.

Typical application areas of clean room technologies:

- pharmaceurical industry

- biotechnology

- healthcare

- automotive

- food industry

- chemical industry

- electrotechnical industry engineering

- engineering

- optics

- aviation and cosmonautics

- cosmetic industry